Aluminum three-dimensional aviation plate

Aluminum three-dimensional aviation plate (also known as aluminum cone core plate)

Classification:

Aluminum three-dimensional aviation plate (aluminum cone core plate)

Keywords: building decoration, decoration engineering

Product Description

Product Introduction

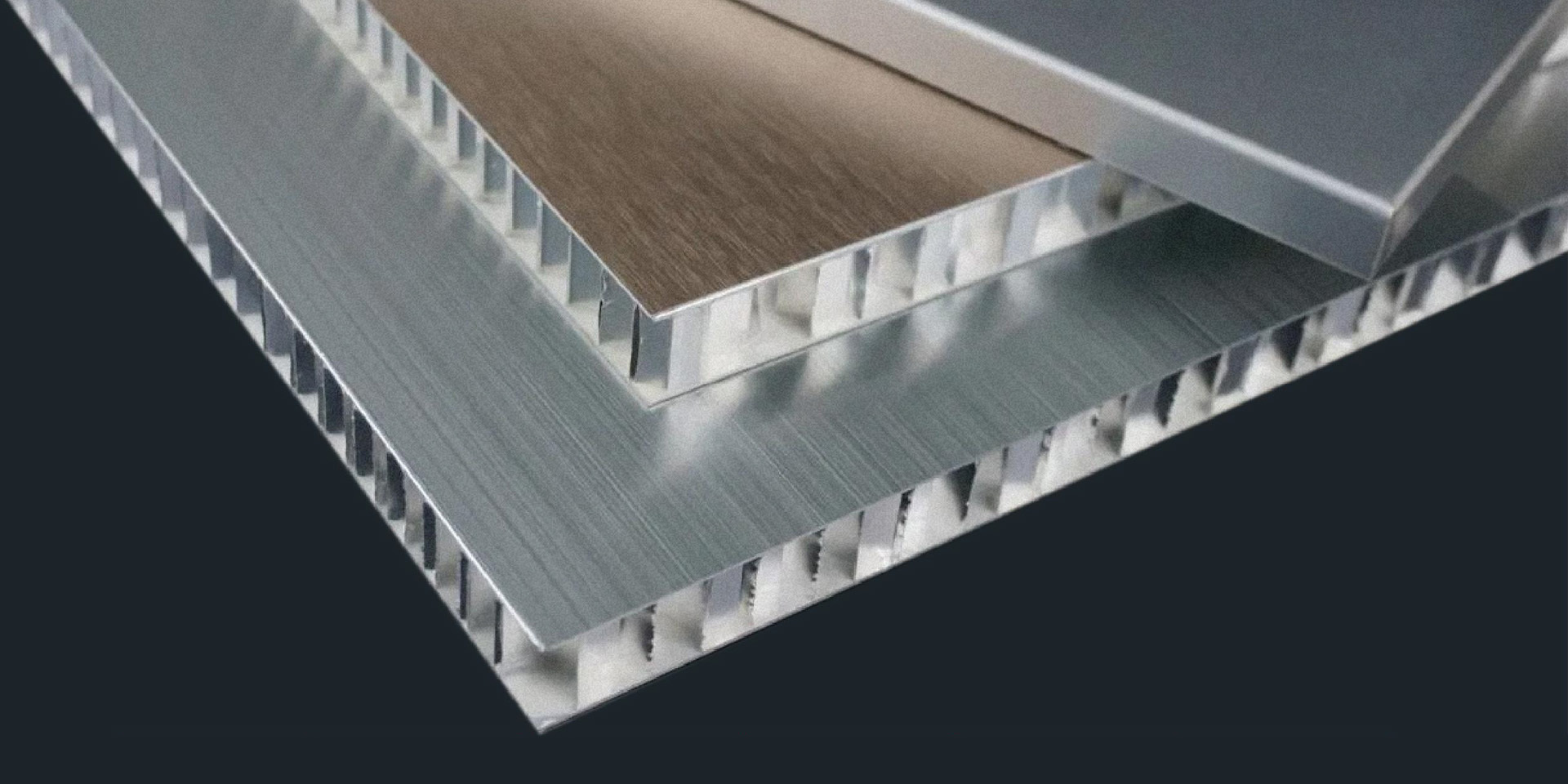

Aluminum three-dimensional aviation plate (also known as aluminum cone core plate) is a full-dimensional three-layer structure, using AL3003 aluminum alloy material, with a unique bonding technology thermal composite. Twenty years of peel strength decay rate of less than 5%. Combining the advantages of a variety of metal curtain wall plates, it has the advantages of excellent flatness, light weight and high strength, small compressive change rate, unique texture, good weather resistance, easy processing, good fire resistance, and high depreciation recovery rate. The unique corner folding structure not only enhances the bending resistance of the plate, improves the wind pressure resistance and cyclic load cycle, but also has better waterproof, anti-corrosion and anti-penetration performance, ensuring the same life of the plate and the building.

Product Features

1. The flatness of the board surface is high, and the change rate of wind pressure resistance is small.

2. Super corrosion resistance, good self-cleaning performance

3. Any shape, meet the beauty of personality

4. Good fire resistance and compliance with fire protection requirements

5. The material is light, easy to process, easy to install

Scope of application

Metal curtain wall panels, interior wall integrated panels, ultra-long (>6m) strip ceilings of public buildings, functional (machine room, operating room) special panels, special decorative panels for ship interior cabins, etc.

Product Structure Diagram

Aluminum three-dimensional aviation plate processing

Cutting:Aluminum three-dimensional aviation plate, use a special cutting machine to cut the plate. After the plate is placed on the worktable with a flat surface and fixed, the plate is aligned and cut. After cutting, the surface is clean and very delicate.

Groove:Grooving is a very important process in the processing of aluminum three-dimensional aviation plate. The back of the plate is cut by 0.2mm, the angle with the best processing angle of 91 is recommend, and the bottom plate and the internal core material are processed together into an angle of 91 °.

1. As shown in the schematic diagram on the left, the sawtooth is processed. The surface is R-5.5 at an angle of 91 °, and the plate is made into sawtooth.

2. When a large number of projects are used for slotting, the production efficiency can be better improved due to the use of slotting saws and mobile mechanical equipment.

Molding:After the slotting process, the product is positioned flat on a plane, and then the bending fixture is bent at 90 degrees to make the plate consistent with the requirements of the design drawing. The bent part of the bend should be kept horizontal after the slot-straight. (Note: In order to prevent deformation and cracking, the cracking degree of the coating in the corner should be above 10C.) The bent edge is at least kept at the design height above 20mm, so that the corner part and the silicone can achieve better waterproof effect and higher performance.

Rounding bends:Under normal circumstances, a large number of ordinary arc bending machines are used for rounding bending. The bending starts with 100mm as the bending line, and the final rounding bending is about 50mm, which can make the rounding design size small and convenient for operation. When bending arc, excellent rounding bending can be made after both sides of the product are combined with teeth. Rounded plates can be used for bending. Due to the difference in the size of corrugations in the middle of the core plate, there are differences in manufacturing and design. Technical personnel should be consulted before production.

Notting processing matters needing attention:

A, double bending and cross-section inconsistency phenomenon:

1. When grooving, the outer plate is processed to remove 0.2mm.

2. There is not enough space for the bending fixture to be inserted into the flange. It is recommended to bend the fixture by inserting the flange to the maximum extent.

3. When slotting, the operator needs to have a high degree of proficiency, and it is recommended to use professional processing technicians.

4. Due to the different specifications of M/C, the pressure is not uniform, which leads to the adverse reaction of the processing depth, and the local bending part is uneven, so the processing pressure of the machine must be kept stable.

B. Core plate and bottom plate fall off phenomenon:

1. In the process of sawing, peeling will occur. During processing, the slotting saw should be fully inspected before processing.

2. When slotting, do not exceed the center line of slot saw processing, resulting in the bending effect can not meet the requirements of the drawing.

Matters needing attention in bending processing:

The number of teeth of the cutter is 8 teeth. When cutting with composite plate, the grooved processing product will have bad deformation. When cutting the edge, the bottom plate will peel off. The number of teeth of the front cutter is 18-24 teeth. It is recommended to use a special bending cutter.

The tool does not use the shape recommended in item 2. If the tip of the blade is used, the flat blade will have uneven corner surface after bending during grooving, resulting in unevenness. It is recommended to use recommend special tools. The angle of the tool width is 90 °, and the 90 ° bending of the flange after cutting is difficult. It is recommended to use a tool with an angle of 91 for cutting.

Prev

Aluminum veneer is made of high quality aluminum plate

Imitation wood grain aluminum veneer

The wood grain aluminum veneer is made of high-quality and high-strength

Imitation stone grain aluminum veneer

The stone aluminum veneer is made of high-quality and high-strength alloy aluminum plate

Single aluminum veneer is the new darling of architectural decoration design.

Leave us a message

What kind of help do I want to give you?

Note: The content with * is required, thank you