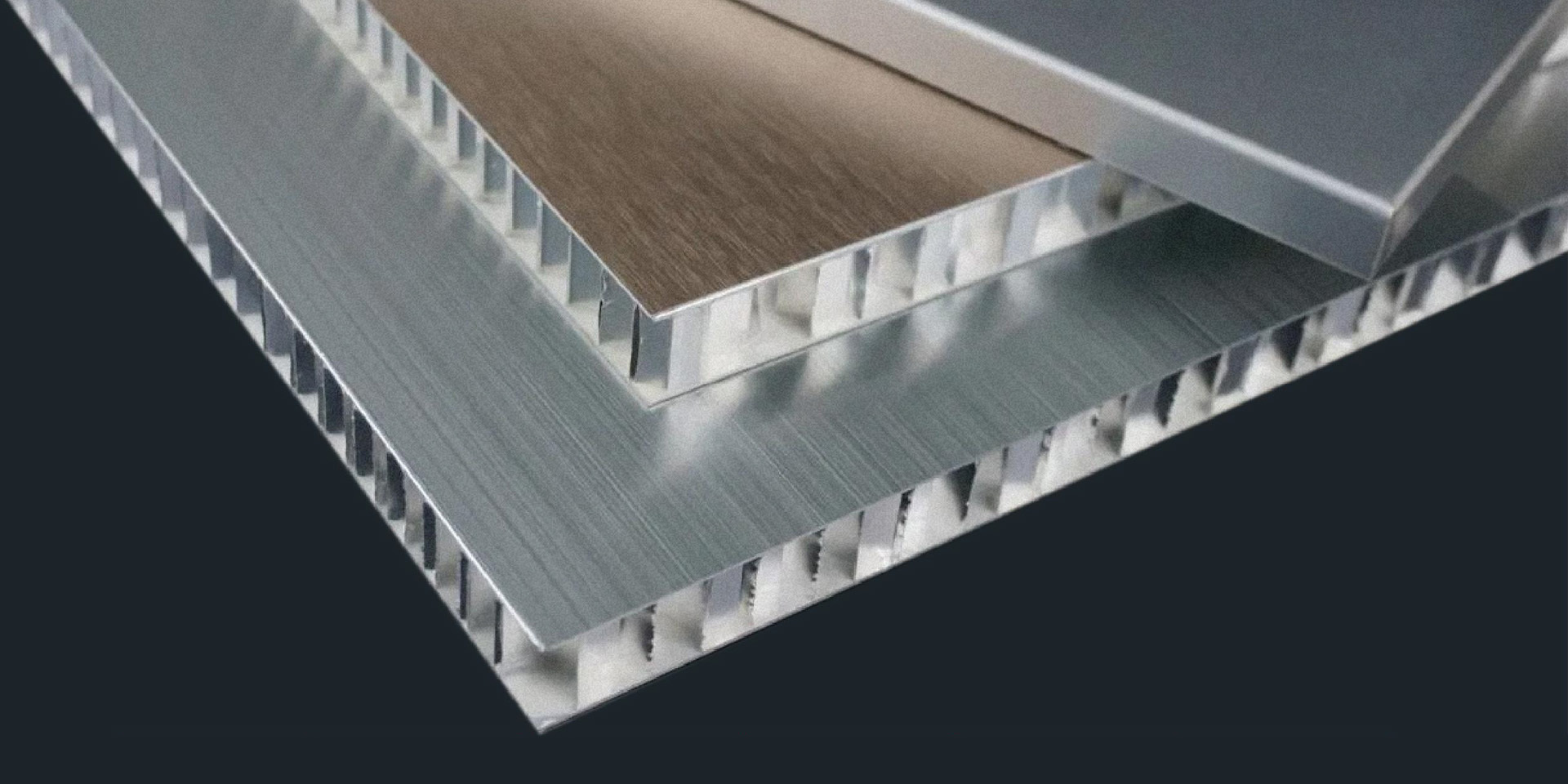

Aluminum-plastic panel

Aluminum-plastic plate, also known as aluminum-plastic composite plate

Classification:

Aluminum-plastic composite plate

Product Introduction

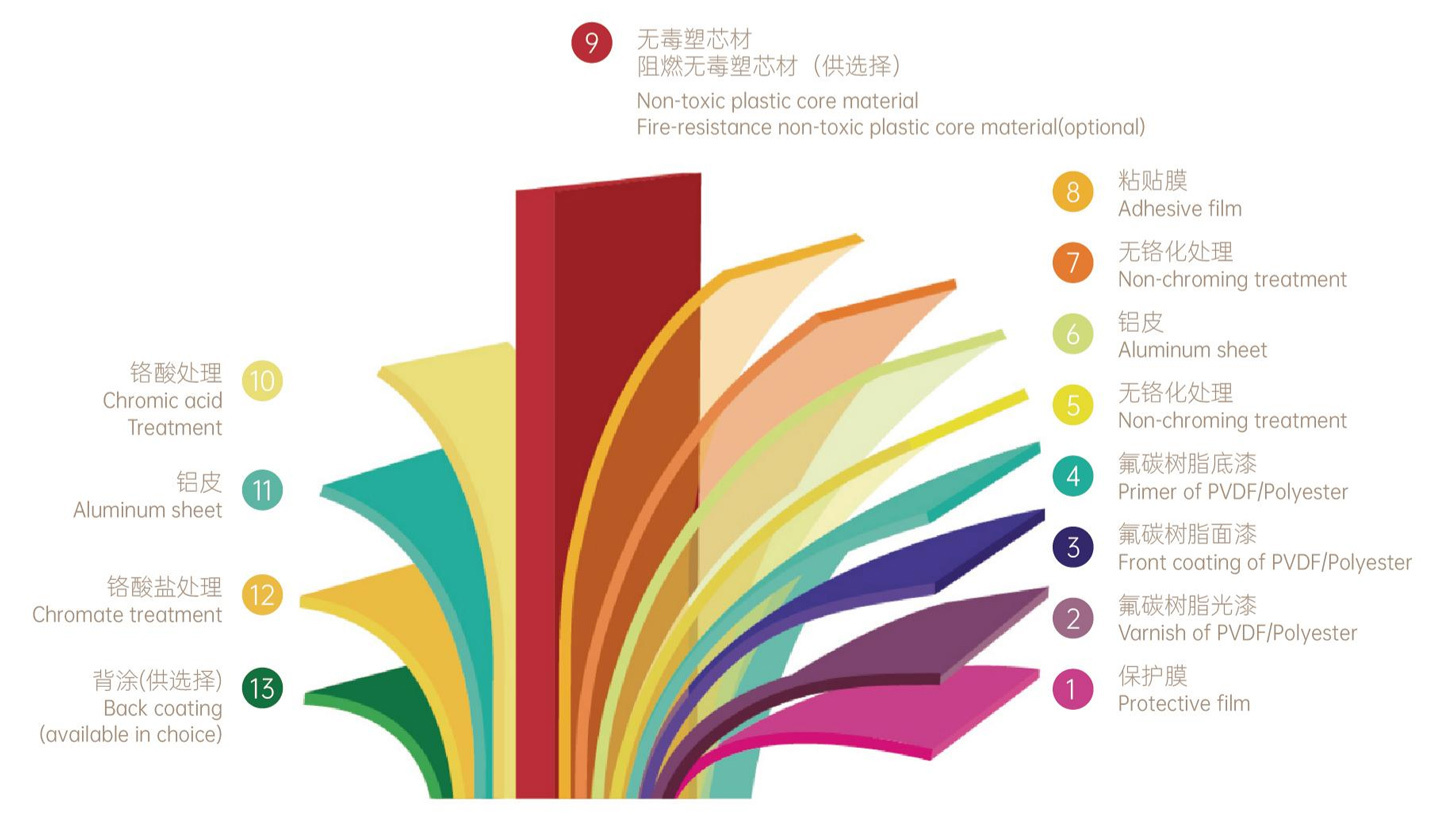

Aluminum-plastic plate, also known as aluminum-plastic composite plate, is a new type of material that has been surface treated and coated with aluminum plate as the surface, polyethylene plastic plate as the core layer, and processed and compounded through a series of technological processes. The aluminum-plastic plate was first developed and produced by a German company, and then improved by a Dutch company and an American aluminum company. The stability of the product quality has reached a high level. The aluminum-plastic plate is composed of two materials (metal and non-metal) with completely different properties. It not only retains the main characteristics of the original composition materials (metal aluminum and non-metal polyethylene plastic), but also overcomes the shortcomings of the original composition materials, thus obtaining many excellent material properties. Such as luxurious and beautiful, gorgeous and colorful decorative: weather resistance, corrosion resistance, impact resistance, fire prevention, moisture resistance, sound insulation, heat insulation, shock resistance, etc.; light weight, easy processing and molding, easy handling and installation, fast construction and other characteristics, these properties for aluminum-plastic panel has opened up a broad application prospect.

Product Features

1. Light weight:

Aluminum plastic plate is composed of aluminum foil and plastic core material with relatively small density, so compared with aluminum plate (or other metal) with the same rigidity or the same thickness, its weight is light and the requirement of wall bearing is low.

2. Good rigidity:

The aluminum-plastic plate skillfully uses the mechanical principle of I-steel structure and skillfully endows it with unique mechanical properties. In addition, the aluminum-plastic plate is compounded under high temperature conditions, and the upper and lower aluminum plates are in a certain tension state during the whole processing process. After cooling and forming, due to the difference in shrinkage rate between the upper and lower symmetrical aluminum plates and the core materials, the plate has stable internal stress and good rigidity.

3. rich color, strong decorative:

The rich color and pattern design meet the coordination of different environmental requirements, make different architectural styles adapt to the environment, and the selected colors are in harmony with the environment, and achieve perfect unity in the overall artistic effect.

4. High surface flatness:

Aluminum-plastic plate is produced by continuous thermal composite production process, and its surface flatness is high. Used for building decoration, with a seamless flat appearance.

5. Excellent fire performance:

The middle of the aluminum-plastic board is a flame-retardant plastic core board, and both sides are extremely difficult to burn aluminum layer. Therefore, it is a safe fireproof material that meets the fire protection needs of building regulations.

6. Good cost characteristics:

The production of aluminum-plastic plate adopts the continuous thermal composite process of spraying metal coils. Compared with the general metal veneer, it has high production efficiency and low raw material cost, and is a material with good cost characteristics.

7. Good environmental performance:

The aluminum and plastic core materials in the discarded aluminum-plastic panels can be recycled by 100%, and the environmental load is low.

Technical parameters of aluminum plastic plate

Product thickness:3mm, 4mm, 5mm, 6mm, 7mm, 8mm (customizable)

Product width:1220mm、1500mm、2000mm

Product length:Can be customized according to the curtain wall design requirements

Product color:According to RAL (international standard color card) or according to customer requirements arbitrary configuration

Aluminium Raw Materials:1100, 3003, 5005 series high quality aluminum

Surface treatment process:Fluorocarbon, polyester, acrylic acid, multi-color series, magic color series, anodized, hillwork, wire drawing, mirror and nano self-cleaning series, etc.

Scope of application:Aluminum-plastic panels are suitable for large building walls, indoor walls, shopping malls, facade decoration, large advertising signs, home appliance backboards, furniture liners, automotive interior panels, renovation of old buildings, etc., are ideal decorative panels.

Prev

Prev